aeCoating™ NexABS-GF25 – High-Performance Glass Fiber Reinforced ABS Filament

Elevate your 3D printing output with aeCoating™ NexABS-GF25, a next-generation ABS filament engineered using a unique co-extrusion skin-core structure and reinforced with 25% chopped glass fibre. This innovative material offers superior strength, dimensional accuracy, and heat resistance, making it the ideal choice for high-performance industrial applications.

Key Features:

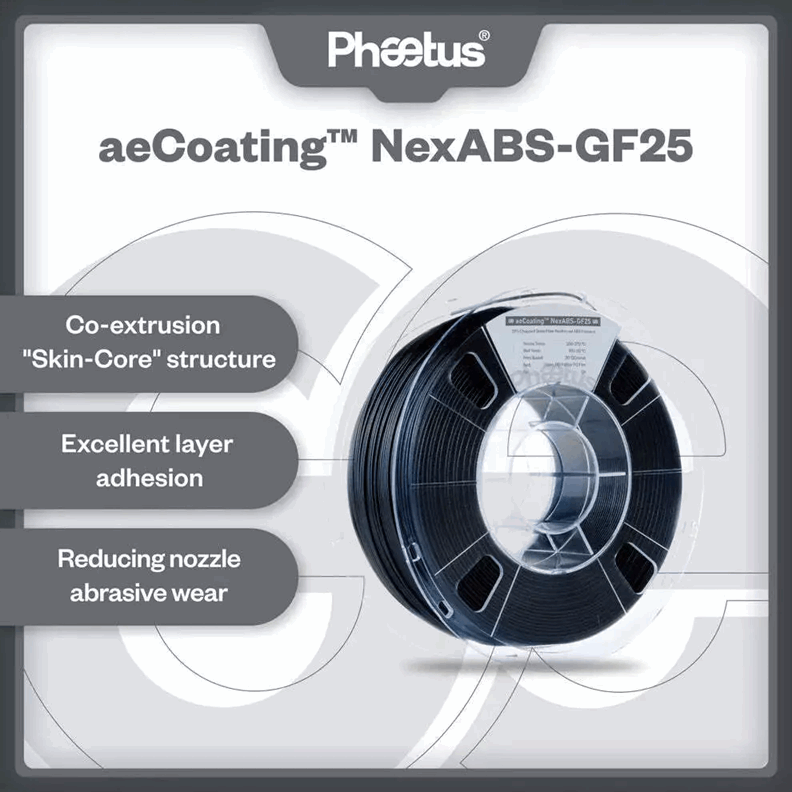

Co-Extrusion Skin-Core Structure: Designed with a pure ABS outer layer for enhanced layer adhesion and a glass fibre-reinforced core for increased mechanical strength and stiffness.

Superior Mechanical Performance: Achieves approximately 48.5 MPa tensile strength in the X-Y axis and 30.5 MPa in the Z-axis, providing consistent strength in all directions.

Exceptional Heat Resistance: With a glass transition temperature of 93°C, this filament outperforms standard ABS in high-temperature environments.

Minimal Warping & Matte Finish: Advanced formulation reduces warping and delivers a clean, matte surface ideal for functional and aesthetic components.

Low Abrasion Printing: The protective co-extrusion layer minimises nozzle wear by reducing direct glass fibre contact, extending the life of your printing hardware.

Technical Specifications:

Filament Diameter: 1.75mm / 2.85mm

Net Weight: 1kg / 2.5kg

Available Colours: Army Green, Grey, Black

Density: 1.15 g/cm³

Glass Transition Temperature: 93°C

Recommended Printing Parameters:

Nozzle Temperature: 250–270°C

Bed Temperature: 100–110°C

Print Speed: 30–120 mm/s

Cooling Fan Speed: 0–30%

Recommended Nozzle Type: Hardened steel, ≥0.4mm diameter

Build Surface: Glass, PEI film, or PC film

Ideal Applications:

Perfect for functional prototypes, mechanical parts, and industrial-grade components requiring exceptional strength, heat resistance, and dimensional stability. Widely used in automotive, aerospace, and manufacturing sectors.

Storage Tips:

Store in a dry environment. If moisture absorption occurs, dry the filament at 70°C for 4–6 hours before printing for optimal performance.

aeCoating™ NexABS-GF25 delivers the strength, reliability, and performance professionals need for demanding 3D printing applications.